Design, Manufacturing, Engineering and Installation

WHAT WE DO

Zander Easy Frame LLC is a Georgia-based company focused on providing Light Steel Framing solutions for builders and DIY home builders in Georgia and the surrounding areas.

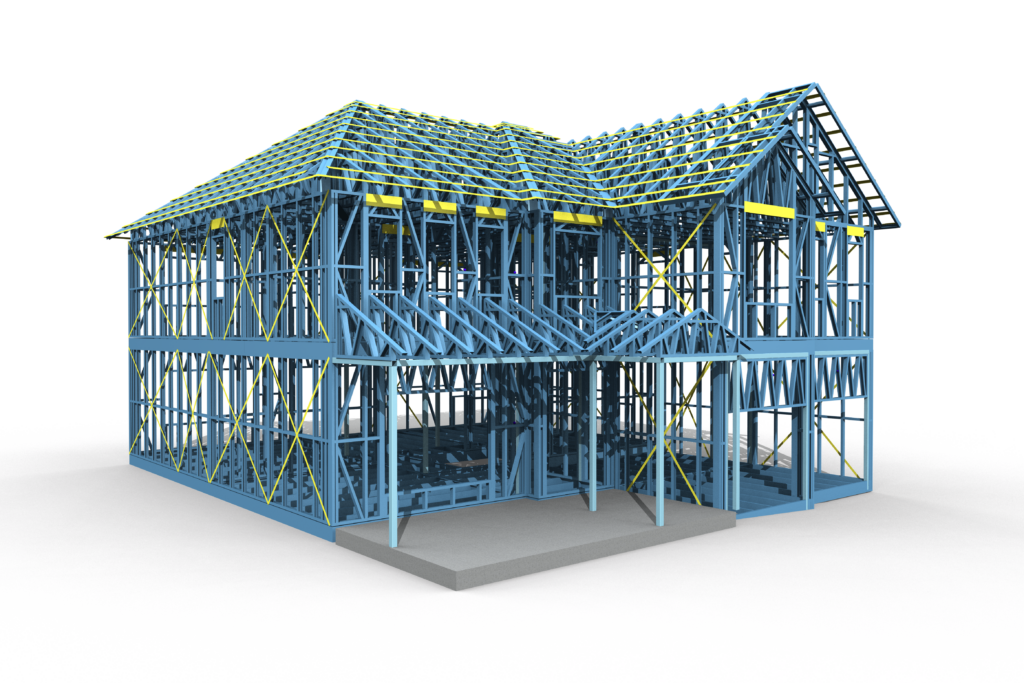

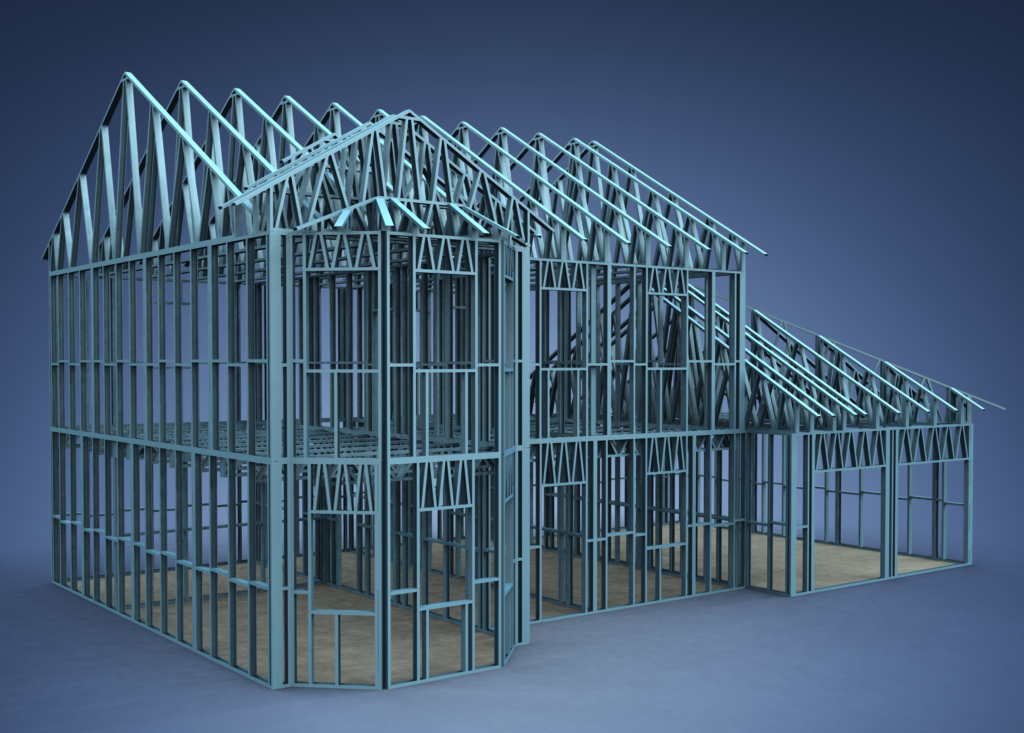

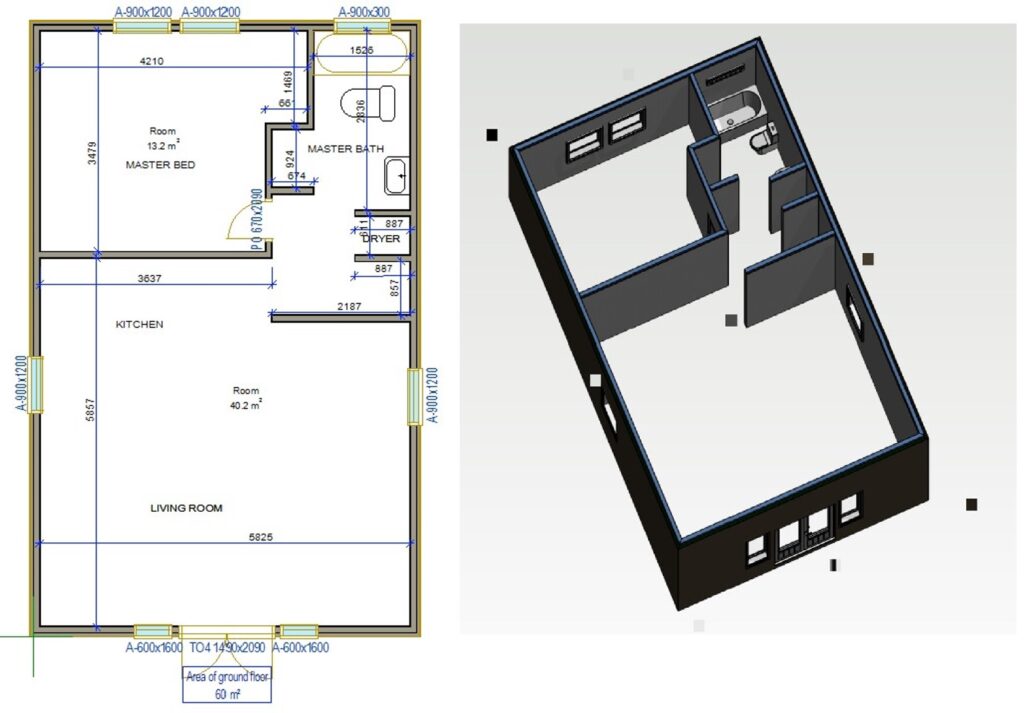

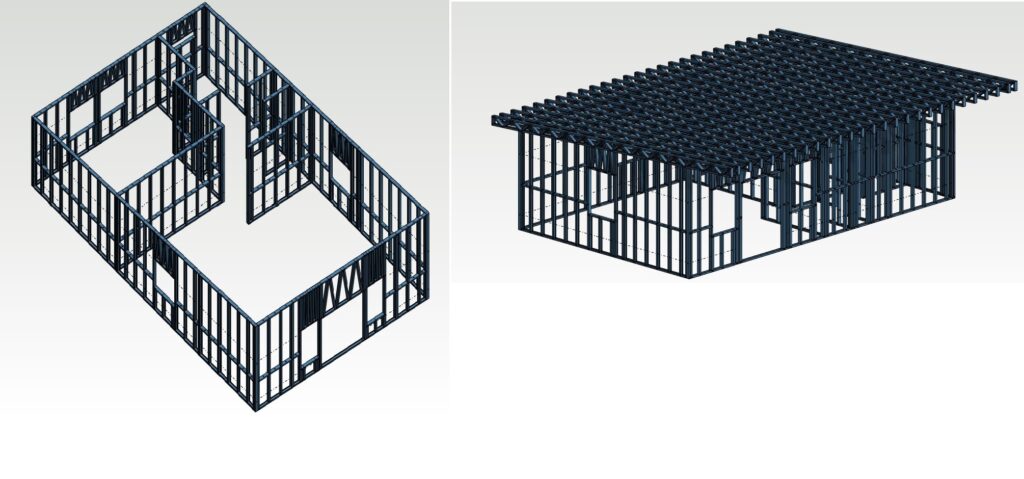

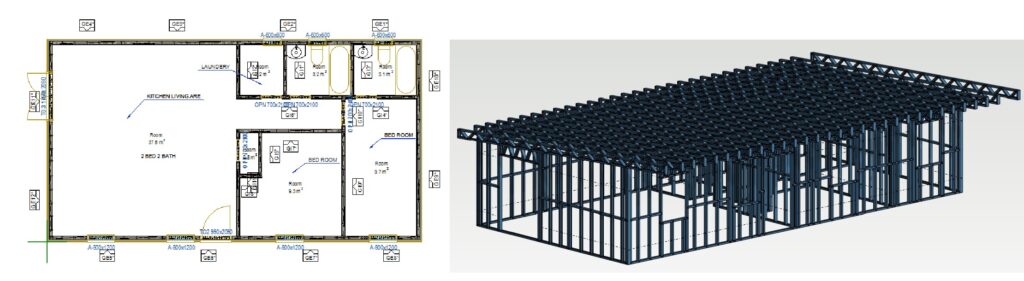

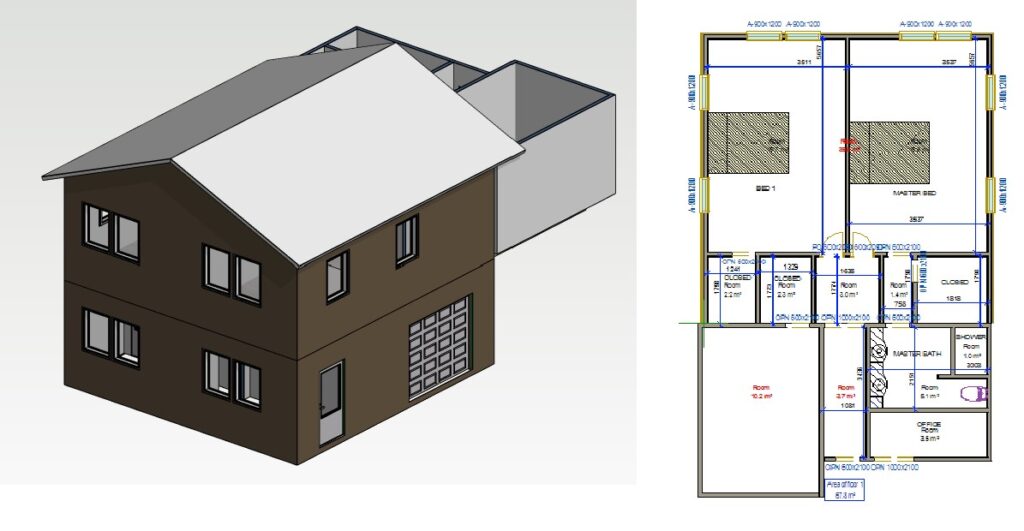

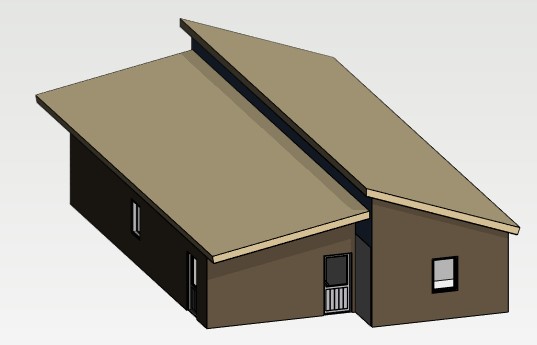

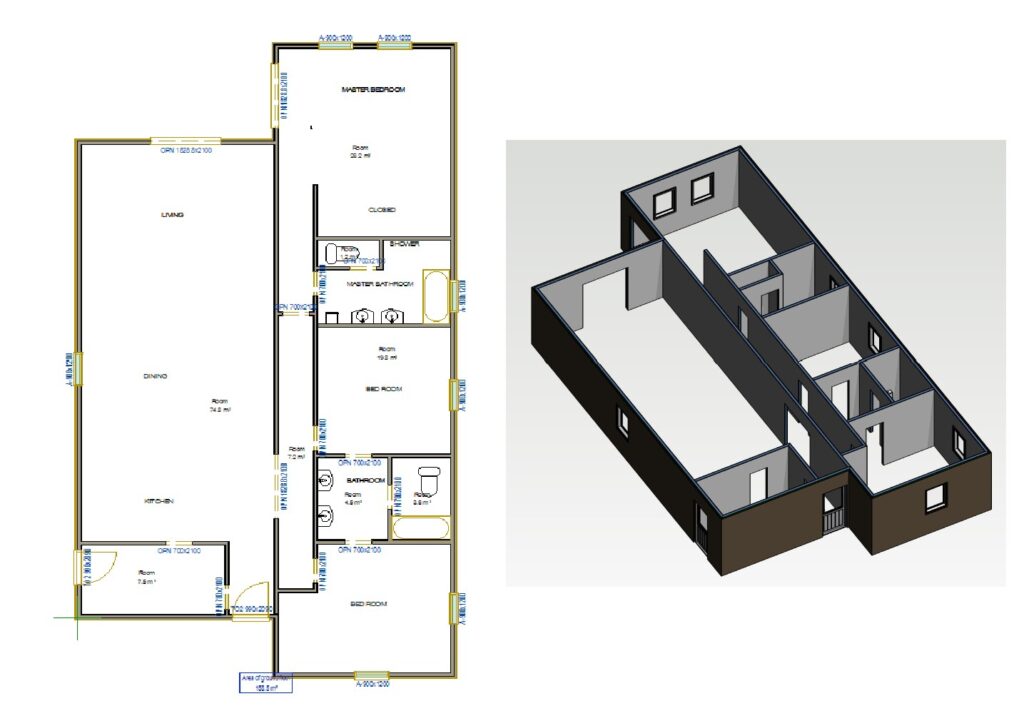

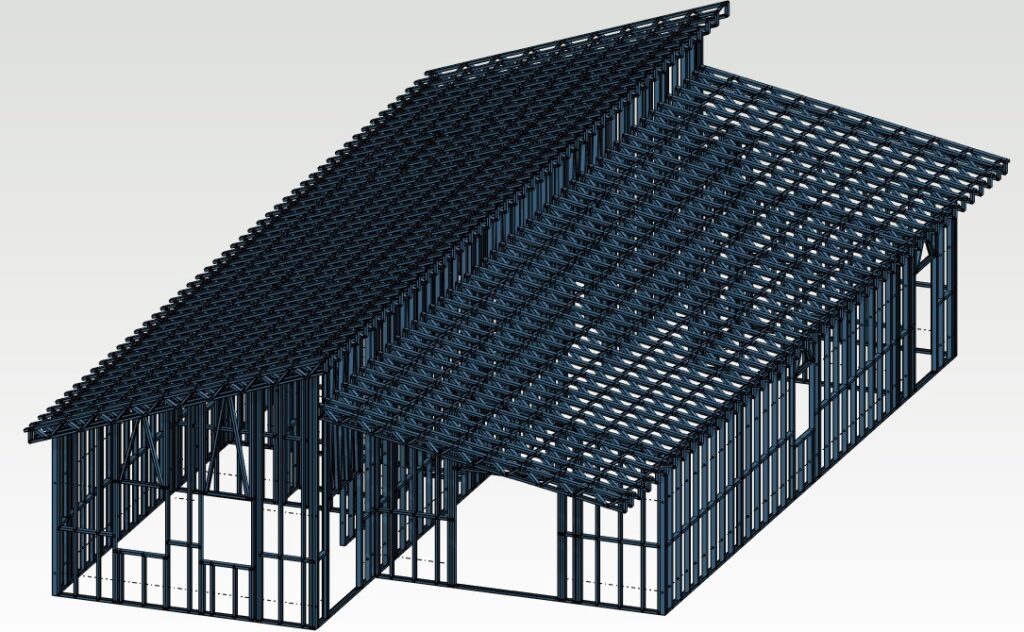

We use cold-formed steel technology and CAD to fabricate and assemble light gauge steel wall panels, floor trusses, and roof trusses.

Panels are shipped to the construction site and are ready for installation upon delivery, ensuring the fastest installation times in the field of framing.

With 15 years of combined experience in all areas, we design, engineer, manufacture, and install—and we can finance your project for you.

Zander Easy Frame is committed to delivering a quality product at an affordable price by using the latest technologies in the framing industry.

SIDING SOLUTIONS

We are 100% committed to eliminating OSB from the equation. Our Steel Siding comes with a 35-year no-fade warranty and is available in 30 vibrant colors to suit any style.

Additionally, we offer AAC (Autoclaved Aerated Concrete) panels which are:

- Fast to Install

- Fireproof

- Acoustically Improved

- Energy Efficient

- Pest Resistant

- Cost-Effective

- Non-Toxic

Benefits of Light Steel Framing

Exceptional Strength-to-Weight Ratio: Steel boasts the highest strength-to-weight ratio of any building material, offering superior structural integrity with a lighter weight and stronger, more reliable connections.

Faster Installation and Reduced Costs: Steel framing allows for quicker installation than traditional wood framing, helping developers reduce labor and carrying costs while accelerating project timelines.

Stable Material Pricing: Historically, steel prices have remained more stable than wood, shielding projects from price volatility and providing more predictable budgeting for developers.

Durability and Longevity: Unlike wood and concrete, steel doesn’t degrade from rot, corrosion, or weather conditions, ensuring lasting structural integrity throughout the lifespan of the building.

No Chemical Protection Needed: Steel framing is naturally resistant to termites, vermin, and other pests—eliminating the need for harmful pesticides or toxins, and enhancing overall safety.

Healthier Living Spaces: Steel is resistant to mold and mildew growth, which can lead to chronic illnesses, ensuring cleaner, healthier environments for building occupants.

No Harmful Off-Gassing: Unlike traditional wood construction, steel doesn’t release harmful chemicals, adhesives, or resins, contributing to better indoor air quality and a more sustainable building environment.

Natural Lightning Protection: Steel is highly conductive, providing multiple paths to safely direct lightning strikes to the ground, reducing fire hazards and improving building safety.

Fire Resistance: Steel framing is inherently fire-resistant, offering enhanced protection against fire damage compared to wood and other materials commonly used in construction.

Sustainability and Recycling: With 67% of steel framing material sourced from recycled steel and 100% recyclable at the end of its life cycle, steel is an environmentally sustainable building choice. This contributes to green building certifications and promotes resource conservation.

Reduced Waste and Landfill Impact: Steel framing reduces construction waste—only about 2% of steel goes to landfills, compared to 20% for lumber—helping builders reduce disposal costs and minimize environmental impact.

Light Steel Framing in Construction

Light gauge steel framing has become a go-to solution for a variety of construction projects, including hotels, mixed-use developments, retail spaces, schools, hospitals, and offices. With the sharpest rise in wood prices in over 70 years and an increasing demand for more environmentally responsible building methods, the adoption of light gauge steel framing has surged across all sectors—industrial, commercial, and residential.

Steel’s remarkable durability and cost-effectiveness have driven the transition from traditional materials to steel framing at an accelerating pace. Cold-formed steel, in particular, has gained traction as the preferred structural frame material for residential and multi-story commercial buildings, offering a superior alternative to conventional products with qualities that far outweigh their limitations.

Safety and Clean Site Advantage

In the construction industry, nearly one-third of reportable injuries result from slips, trips, and falls, with these incidents leading to 50% more days away from work compared to other types of injuries. Workers in construction are 71% more likely to be injured than those in any other industry, with nearly 10% of these injuries resulting in missed workdays.

A clean and organized construction site is crucial to reducing these risks. Light Steel Framing (LSF) significantly contributes to a safer work environment by reducing material waste on-site. Since LSF panels are prefabricated off-site, the amount of waste and clutter on-site is minimized, leading to clearer pathways for workers and reducing the likelihood of accidents.

The modular system also speeds up construction, allowing for faster assembly and reducing the time workers spend on-site, further decreasing the chances of injury. The elimination of cutting…

Safety and Clean Site Advantage

In the construction industry, nearly one-third of reportable injuries result from slips, trips, and falls, with these incidents leading to 50% more days away from work compared to other types of injuries. Workers in construction are 71% more likely to be injured than those in any other industry, with nearly 10% of these injuries resulting in missed workdays.

A clean and organized construction site is crucial to reducing these risks. Light Steel Framing significantly contributes to a safer work environment by reducing material waste on-site. Since LSF panels are prefabricated off-site, the amount of waste and clutter on-site is minimized, leading to clearer pathways for workers and reducing the likelihood of accidents.

The modular system also speeds up construction, allowing for faster assembly and reducing the time workers spend on site, further decreasing the chances of injury. The elimination of cutting and scrap waste from the site directly reduces material mishaps and other hazards. Additionally, steel has a much lower scrap rate compared to wood, with less than 1% of steel waste ending up on-site, compared to as much as 25% for wood.

By reducing clutter, speeding up installation, and lowering waste, Light Steel Framing creates a safer, cleaner, and more efficient work environment, leading to fewer injuries and a more streamlined construction process.

Insurance Costs

Insurance is a significant expense for developers and property owners in the construction industry. However, by utilizing Light Steel Framing (LSF), owners, developers, and general contractors can significantly reduce their risk of damage or loss, leading to substantial savings on insurance premiums. LSF can lower builder’s risk insurance, general liability, and coverage for bodily harm and property damage by as much as 40% compared to traditional construction methods.

Steel structures offer several benefits that contribute to these savings. They are fire-resistant, reducing the likelihood of fire damage and the associated costs. Steel buildings are also more cost-effective to build and own, with enhanced durability, energy efficiency, and lower maintenance requirements over their lifespan.

The versatility of steel allows for the construction of any type of building while maintaining its strength and integrity. Steel’s resistance to ignition and its ability to slow the spread of fire provide critical time for occupants to safely evacuate in the event of a fire. Additionally, steel buildings sustain far less damage from fires than wood-framed buildings, further reducing the need for costly repairs and insurance claims.

By choosing Light Steel Framing, developers can not only lower their insurance costs but also enjoy a safer, more durable, and cost-effective building option.

Advanced Architectural Drywall Profiles

aadprofiles.com

AAD Profiles

Our mission is to provide customers with a professionally finished, pre-fabricated drywall product at a price better than traditional drywall methods. This product has been systematically fabricated to reduce labor, material costs, time, and waste. By using this custom product, you’ll increase your chances of winning more project bids by enhancing possibilities, quality, and efficiency, while making the drywall contractor’s project experience easier and faster.

Pre-Cut Drywall

Every room at a Zander Easy Frame House comes with a pre-cut drywall package from AADPROFILES.COM.

There is no waste on site .Save up tp 50% on mud ,no corner bead ,faster instelation and save on dumster fees